Introduction to the production of fishing nets

Modern production of fishing nets requires a careful approach to the selection of equipment. For businesses operating in this space, it is important to consider the type of networks that will be produced, as well as the available resources and budget. The company Tao-Bao.KZ offers its customers equipment from China for the manufacture and weaving of fishing nets of all types and sizes, from manual machines to fully automated systems.

Types of nets and their production

Fishing nets are of different types, depending on the weaving technology used and the intended purpose. There are several main types:

- Single-walled nets (gill nets) is a classic choice for many fishermen, suitable for fishing in shallow and medium waters.

- Dual Networks – provide a more reliable catch and stability in sea and deep-sea fishing conditions.

- Hostless networks – are manufactured using knot-free technology, which makes them less visible and increases durability.

The production of such nets can be carried out using various machines adapted to each type.

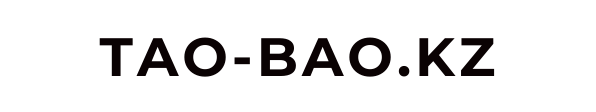

Equipment for weaving fishing nets

There are many models of machines for the production of nets on the modern market, from simple semi-automatic devices to high-tech automated systems. The company Tao-Bao.KZ selects equipment taking into account the needs of customers, providing a full range of services - from finding a suitable model to delivery and installation at the customer's enterprise.

Automatic Net Knitting Machines

Automatic machines allow you to produce large volumes of nets with high speed and accuracy. These devices are programmed to perform patterns and weaves of varying complexity, ensuring minimal operator intervention. Some popular models include:

- Keestar GN 20-6 – a highly efficient machine for knitting single knots.

- Newlong HR-4N is an ideal choice for small industries due to its compactness.

- Union Special 81500CZ – specialized equipment for complex nodal circuits and multitasking use.

Semi-automatic machines

Semi-automatic machines provide the opportunity to partially automate the process. It is a good choice for small companies or workshops where a balance between performance and equipment cost is important. These machines help speed up production without the need for a complete transition to automation.

Manual production of nets

For small businesses and amateur level there is equipment for manual production of nets. It allows the production of small batches of customized nets, which makes them more flexible in production and suitable for specialized tasks.

How to choose a machine for the production of nets

When choosing equipment for weaving fishing nets, there are many factors to consider:

- Target production volumes – automatic and semi-automatic machines are suitable for mass production of nets, and manual machines can be used for small-scale production.

- Type of network produced – nodal and knotless technologies require different approaches and machines.

- Budget and opportunities for expansion – It is important to take into account the cost of equipment and the possible costs of maintenance and renewal of equipment.

Workspace organization and preparation for production

For successful work with equipment, it is important to properly organize the production area. It is necessary to take into account:

- Ergonomics – the placement of machines should take into account the convenience of the operator and safe movement around the production.

- Lighting and ventilation – In the production of networks, good lighting conditions for accuracy of work and high-quality ventilation for the safety of the operator are important.

- Hardware Support – regular maintenance is also required to maintain the performance of the machines.

Technical equipment of the workshop

In addition to the machines, the workshop should be equipped with additional devices for the preparation of raw materials, trimming, processing the ends of cords and quality control of finished products.

Main Materials for Fishing Net Production

Nets can be made of various materials, such as:

- Monofilament – is durable, lightweight and highly resistant to water.

- Multifilament – usually more flexible and suitable for deep-sea nets.

- Nylon thread is a traditional material for nets, which has good resistance to wear.

The choice of material depends on the specific requirements and budget of the client.

Use of stabilizers and nodal machines

To ensure the stability of the knots and the durability of the nets, special stabilizers are used, as well as sewing machines for securing cords and processing the ends. This equipment helps maintain high quality and extends the lifespan of networks.

Profitability of the fishing net business

Fishing net manufacturing is a lucrative business, especially with the growing demand for fishing commodities. Tao-Bao.KZ helps customers assess the return on investment of equipment by offering solutions for small enterprises and large productions.

How to Start a Fishing Net Business

Before starting a business, it is important to draw up a business plan, which includes the following stages:

- Study of the market and competitive environment – analysis of competitors and potential demand for products.

- Selection of equipment and supplier – Selection of suitable machine models and trusted suppliers.

- Paperwork and permits – registering a business, choosing a tax system and obtaining the necessary permits.

- Organization of logistics and sales channels – development of a supply scheme and access to target markets, such as Kazakhstan, Russia and the CIS countries.

Business ROI Assessment

The profitability of a business depends on the initial investment in equipment, the cost of raw materials and distribution channels. It is important to consider possible additional maintenance and marketing costs.

Selection of equipment for knitting fishing nets

The Tao-Bao.KZ company provides services for the selection and supply of equipment for all types of production networks. Depending on your needs and budget, our experts will help you choose the optimal machine model, as well as organize the delivery, installation, and training of personnel.

Equipment from China as a profitable solution

Chinese manufacturers offer a wide range of quality net-weaving equipment at affordable prices. This allows for high profitability and flexibility in the organization of production.

Conclusion

Setting up a business for the production of fishing nets is a promising niche with high potential. Selecting high-quality equipment from China with the help of Tao-Bao.KZ will provide your customers with a reliable and efficient production process, which will help the company successfully develop and enter new markets.